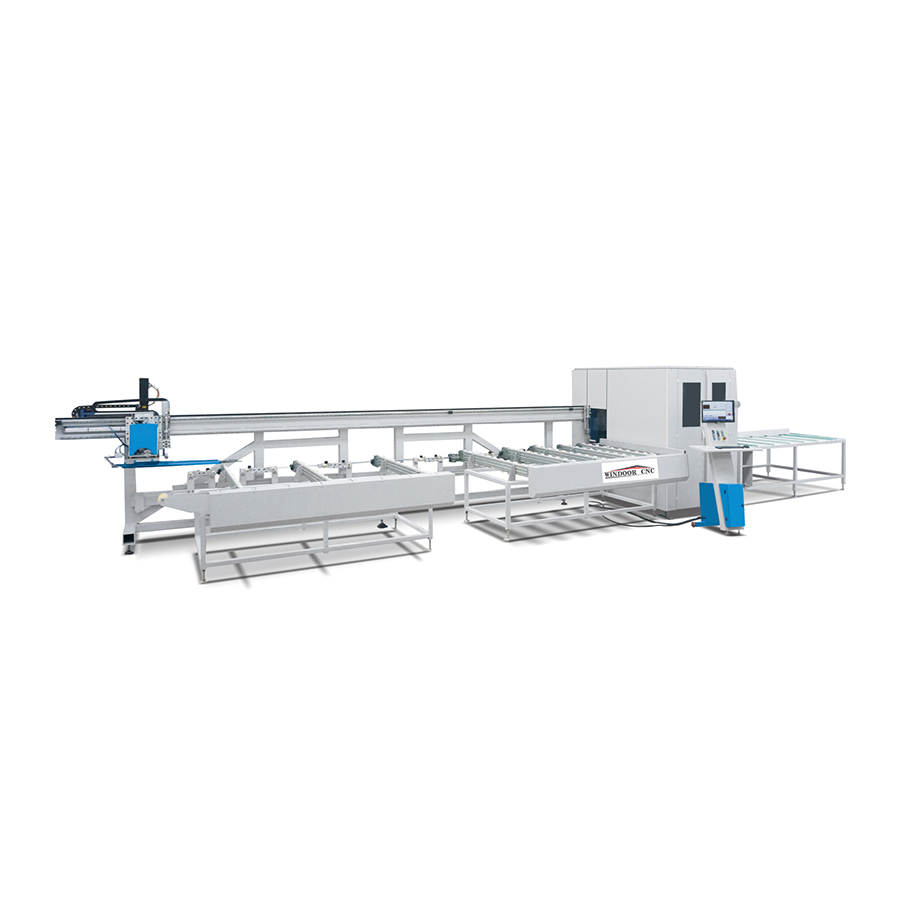

Cutting Center for Aluminum and PVC profiles WDMC02

Cutting Center for Aluminum and PVC profiles WDMC02

Features

It can automatically download and optimize the data of PVC cutting and technical parameters of processing, no need manual input and adjust

Automatic accomplish profile holding, feeding and cutting, high automation.

with Circle feeding system, highly improves the production efficiency.

High-precision spindle motor, to ensure the high quality of processing.

High-speed feeding system, high production efficiency I

Adopt the linear bearing system for higher precision processing.

Adopt three- axis CNC system for high degree of automation.

Well-known brand driven system, high precision.

Fully adopt high quality electrical and pneumatic components with stability and high reliability.

It can communicate with PC and choose processing task automatically and accomplish CAD/CAM flexibly

Barcode printer is available which print the label with material information in time to accomplish identification of processing information and material management. (software support)

With automatic unloading system, simple and convenient operation.

With automatic waste profile collection system, to keep the working environment clean and tidy.

Worktable and the body height are designed by ergonomic principle, reduce labor intensity.

Large 17-inch control screen, together with the graphical interface, simple and intuitive operation.

Suitable for volume and high-quality production of complex window-type.

Technical parameters

| Voltage | 380V 50Hz |

| Input Power | 15.5KW |

| Air Pressure | 0.5~ 0.8MPa |

| Air Consumption | 400L /min |

| Rotary Speed | 3000 r/min |

| Saw Blade Specification | φ 500mm x 4.3mmxφ30mm |

| Max. Cutting Width | 120mm (Single Piece) |

| Range of Profile Processing Length | Max 6000mm(According to requirement) |

| Cutting Height | |

| Frame/Sash | ≤120mm |

| Mullion | 54-120mm |

| V-notch Depth | ≤(60mm) |

| Min. Cutting Length | |

| Frame/Sash | 300mm |

| Overall Dimension | 12500mm x 4100mm x 2100mm |

| Weight | 3600kg |